VCI Paper

Price 25 INR/ Square Meter

VCI Paper Specification

- Size

- Customizable

- Thickness

- Standard

- Feature

- VCI technology for rust prevention

- Adhesive Side

- Single-sided

- Shape

- Rectangular

- Material

- Paper

- Usage

- Industrial metal packaging storage and shipping

- Form

- Sheet

- Color

- Brown

- Application

- Metal corrosion protection

About VCI Paper

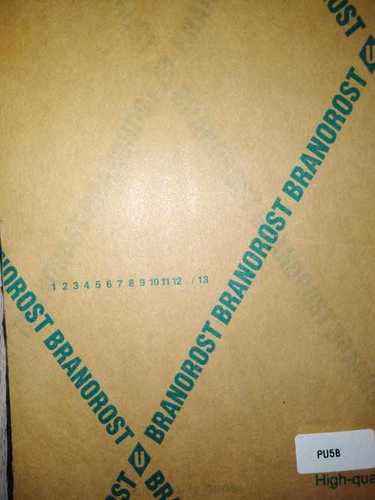

BRANO rost is a high quality kraft paper combined with the premium VCI quality of BRANO pac.

By emitting constantly a small amount of active anticorrosion substances inside of the packaging (VCI principle Volatile Corrosion Inhibitor), BRANOrost papers helps to protect metal parts during transport and storage.

Active VCI agents effuse and build up a protecting atmosphere, which protects reliably against rust, even after having opened the package for a short time the protecting atmosphere can be rebuild immediately.

BRANOrost is double side active on contact and distance. It can be used as a simple single wrap, interlayer or lining material.

Advanced VCI Technology for Rust Prevention

Utilizing modern VCI technology, these sheets emit corrosion-inhibiting vapors that safeguard metal surfaces against rust and oxidation. This makes them ideal for long-term packaging, storage, and transportation, ensuring your metal parts remain in prime condition without the use of traditional oils or greases.

Customizable and User-Friendly Design

Available in a range of customizable sizes and standard thicknesses, our brown, rectangular sheets fit a variety of packaging requirements. The single-sided adhesive simplifies application, making them suitable for both automatic and manual packaging lines in busy industrial environments.

Manufactured and Supplied in Germany

Backed by leading German manufacturing standards, these VCI Paper Sheets are distributed nationwide to industrial clients. Rigorous quality checks ensure consistent performance and reliability, addressing the protective demands of metal processing and supply sectors.

FAQ's of VCI Paper:

Q: How does VCI Paper protect metal items from corrosion?

A: VCI Paper releases specialized corrosion-inhibiting vapors that form a protective molecular layer on metal surfaces, blocking moisture and oxygen. This prevents rust and corrosion during storage and shipping, especially in industrial settings.Q: What materials and features make VCI Paper effective for metal packaging?

A: Constructed from high-quality brown paper combined with advanced VCI technology, these sheets offer single-sided adhesion and customizable sizing. They are designed for industrial metal packaging and are particularly effective due to their rust-preventative properties.Q: When should VCI Paper sheets be used in industrial operations?

A: VCI Paper sheets are recommended whenever metal components are packaged for storage or transit, particularly in environments prone to humidity or temperature fluctuations, to ensure protection against corrosion throughout the supply chain.Q: Where are these VCI Paper sheets manufactured and supplied?

A: Produced with strict quality standards in Germany, these sheets are distributed and supplied to industrial clients across the country, supporting manufacturers, distributors, and suppliers with reliable corrosion protection.Q: What is the process for applying VCI Paper during packaging?

A: Simply cut the VCI Paper sheet to the desired size and place it so the single adhesive side is in contact with the metal component. Ensure the metal is fully covered for optimal protection until the item is in use.Q: How can using VCI Paper benefit industrial metal storage and shipping?

A: Using VCI Paper minimizes rust-related damages, reduces the need for messy oils or desiccants, and simplifies cleanup. It saves costs on repairs and maintenance of metal parts, ensuring efficiency throughout storage and shipment pipelines.Q: Is the size of the VCI Paper customizable to specific packaging needs?

A: Yes, VCI Paper sheets can be cut or ordered to custom sizes, catering to a wide range of industrial packaging requirements for various shapes and dimensions of metal products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in VCI Papers Category

Branorost U VCI Paper

Price 24 INR / Square Meter

Minimum Order Quantity : 35 Square Meters

Color : brown

Application : steel, cast iron (only on contact), chrome, copper, brass, zinc, , bronze, highgrade aluminum, nonferrous metal

Size : as per requirement

Ferrogard Papers

Price 26 INR / Square Foot

Minimum Order Quantity : 1000 Square Foots

Color : White

Application : Industrial

Size : Standard

Purity(%) : 99 %

Branorost U Premium VCI Paper

Price 24 INR / Square Meter

Minimum Order Quantity : 200 Square Meters

Color : Brown

Application : Industrial

Size : Standard

Purity(%) : 99 %

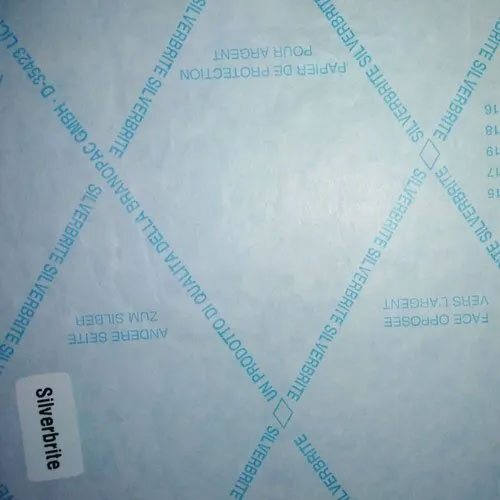

Tarnish Protection SilverbritePaper

Price 160 INR / Square Meter

Minimum Order Quantity : 100 Square Meters

Color : Sky Blue

Application : Industrial

Size : Standard

Purity(%) : 99 %

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese