Vacupack Aluminum Foil

Price 960 INR/ Kilograms

Vacupack Aluminum Foil Specification

- Product Type

- Aluminum Foil

- Material

- Aluminum

- Type

- Roll

- Alloy Condition

- 8011

- Treatment

- Soft

- Reflectivity %

- 85%

- Temperature Range

- -40C to +600C Celsius (oC)

- Hardness

- Soft

- Width

- 300 mm Millimeter (mm)

- Length

- 100 m Meter (m)

- Size

- 300 mm x 100 m

- Color

- Silver

- Toxicity

- Non-toxic

- Usage

- Food Packaging, Pharmaceutical, Household

- Roll Weight

- Varies as per thickness/length

- Grade

- Food Grade

- Surface Finish

- Glossy/Matte

- Heat Sealable

- Yes

- Recyclable

- Yes

- Moisture Proof

- Yes

Vacupack Aluminum Foil Trade Information

- Minimum Order Quantity

- 200 Kilograms

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 10000 Kilograms Per Day

- Delivery Time

- 7-15 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- DEKRA/ REACH

About Vacupack Aluminum Foil

Water vapor transmission rate: less than 0.02 g/m2.C

Specification

|

Usage/Application |

sea worthy packaging |

|

Brand |

Branopac |

|

Thickness |

133 |

|

Material |

Aluminium Composite foil |

|

Color |

Silver |

|

Treatment |

Composited |

Premium Food Grade Protection

Vacupack Aluminum Foil is manufactured using high-quality 8011 alloy, certified for food-grade safety. Its non-toxic and moisture-proof properties ensure that packaged items remain fresh and uncontaminated, making it reliable for culinary and pharmaceutical applications.

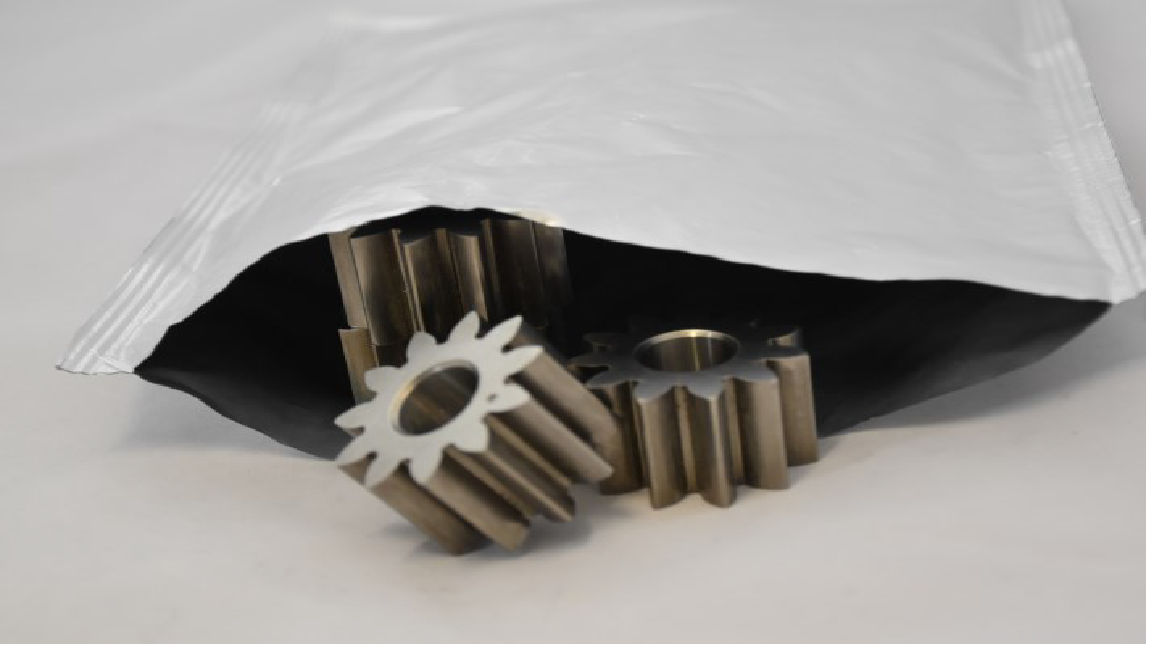

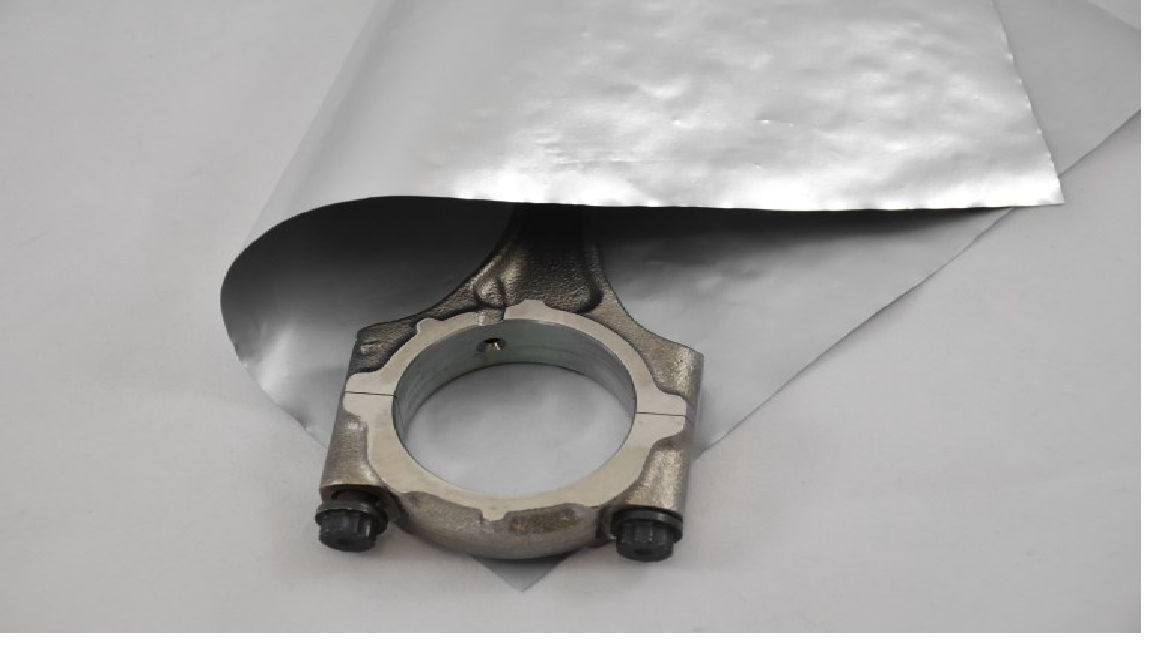

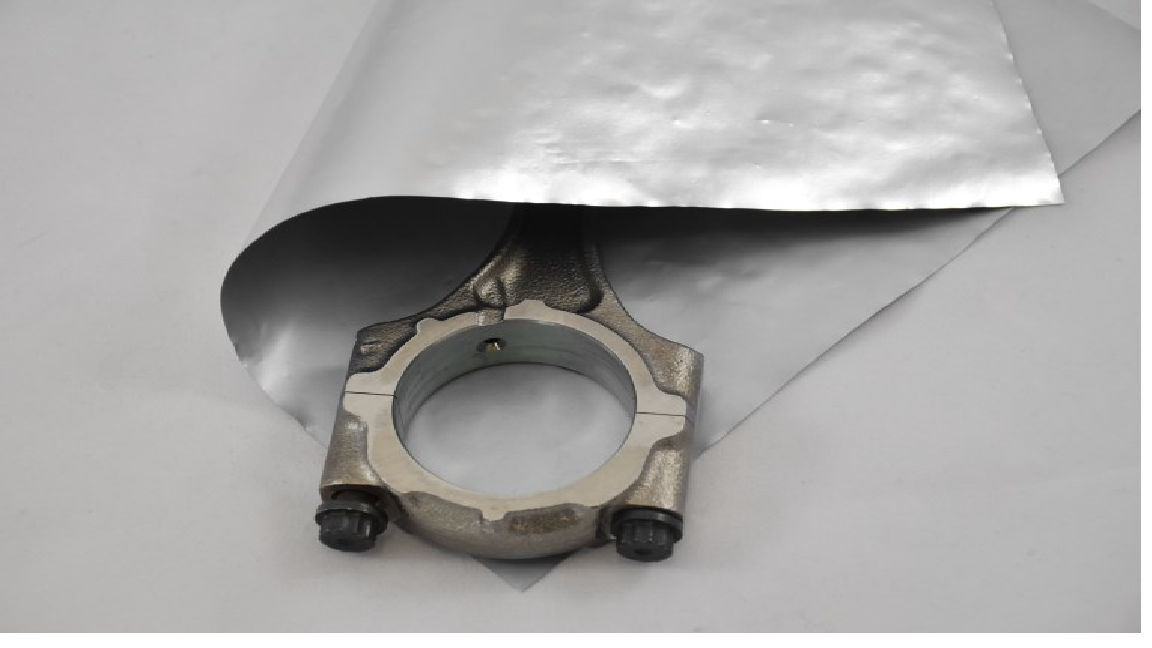

Flexible Packaging Solutions

Offered in rolls of variable weight adjusted by thickness and length, Vacupack foil adapts seamlessly to diverse requirements. Soft-tempered and heat sealable, it easily wraps around foods or sensitive materials, delivering convenience and versatility in both household and professional environments.

Sustainable and Efficient

This foil is fully recyclable, contributing to eco-friendly practices and responsible waste management. With a high reflectivity rate and temperature resilience from -40C to +600C, it provides exceptional thermal efficiency for grilling, storing, or pharmaceutical wrapping.

FAQ's of Vacupack Aluminum Foil:

Q: How does Vacupack Aluminum Foil ensure food safety?

A: Vacupack foil is manufactured from alloy 8011 with a food-grade rating, guaranteeing it is non-toxic and safe for direct contact with consumables. Its moisture-proof and heat-sealable features also maintain hygiene and freshness.Q: What are the main applications for this aluminum foil?

A: The primary uses include food packaging, pharmaceutical wrapping, and general household tasks. Its robust properties make it suitable for storing, cooking, and protecting products across these sectors.Q: Where can I use Vacupack Aluminum Foil given its temperature range?

A: You can safely use this foil for operations ranging from deep freezing at -40C to high-temperature baking or grilling up to +600C, making it ideal for kitchens, labs, and industrial packaging lines.Q: What process is recommended for sealing packages with this foil?

A: Vacupack Aluminum Foil is heat sealable. Use compatible sealing machines or manual pressing with controlled heat to securely close packages, ensuring an airtight and moisture-proof barrier.Q: How is Vacupack Aluminum Foil beneficial for the environment?

A: The foil is recyclable, reducing landfill waste and promoting resource conservation. Its durable construction allows reusing where possible, supporting sustainable practices.Q: When should I choose glossy versus matte finish for packaging?

A: Glossy finishes provide enhanced reflectivity, ideal for heat insulation and aesthetic appeal, while matte surfaces are often preferred for labeling and reducing glare. Selection depends on the intended application and visual preference.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

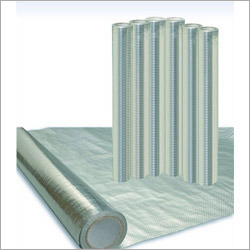

More Products in Aluminium barrier Foil for Machine & Seaworthy pac Category

Aluminium Barrier Foil

Price 960 INR / Kilograms

Minimum Order Quantity : 200 Kilograms

Alloy Condition : 8011 / 1235 / Custom

Width : Up to 1500 mm Millimeter (mm)

Temperature Range : 40C to +85C Celsius (oC)

Material : Other, Aluminium, Multilayer Laminates

VCI Aluminum Barrier Foil

Price 75 INR / Meter

Minimum Order Quantity : 200METER

Alloy Condition : 8011, 1235 Aluminum Alloy

Width : Custom, typically 1000 mm 1200 mm

Temperature Range : 30C to +80C

Material : Other, Laminated Aluminum Foil with VCI additives

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese