Branorost R Chips

Price 1050 INR/ Square Meter

Branorost R Chips Specification

- Feature

- Protection from Rust/Corrosion

- Size

- standard and as per requirement

- Shape

- cutsheet

- Material

- VCI Paper

- Color

- White

- Application

- Protects steel, chromium, tin, pure aluminium and cast iron

Branorost R Chips Trade Information

- Minimum Order Quantity

- 35 Square Meters

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 10000 Square Meters Per Day

- Delivery Time

- 7-10 Days

- Packaging Details

- Standard

- Main Domestic Market

- All India

- Certifications

- DEKRA/ REACH

About Branorost R Chips

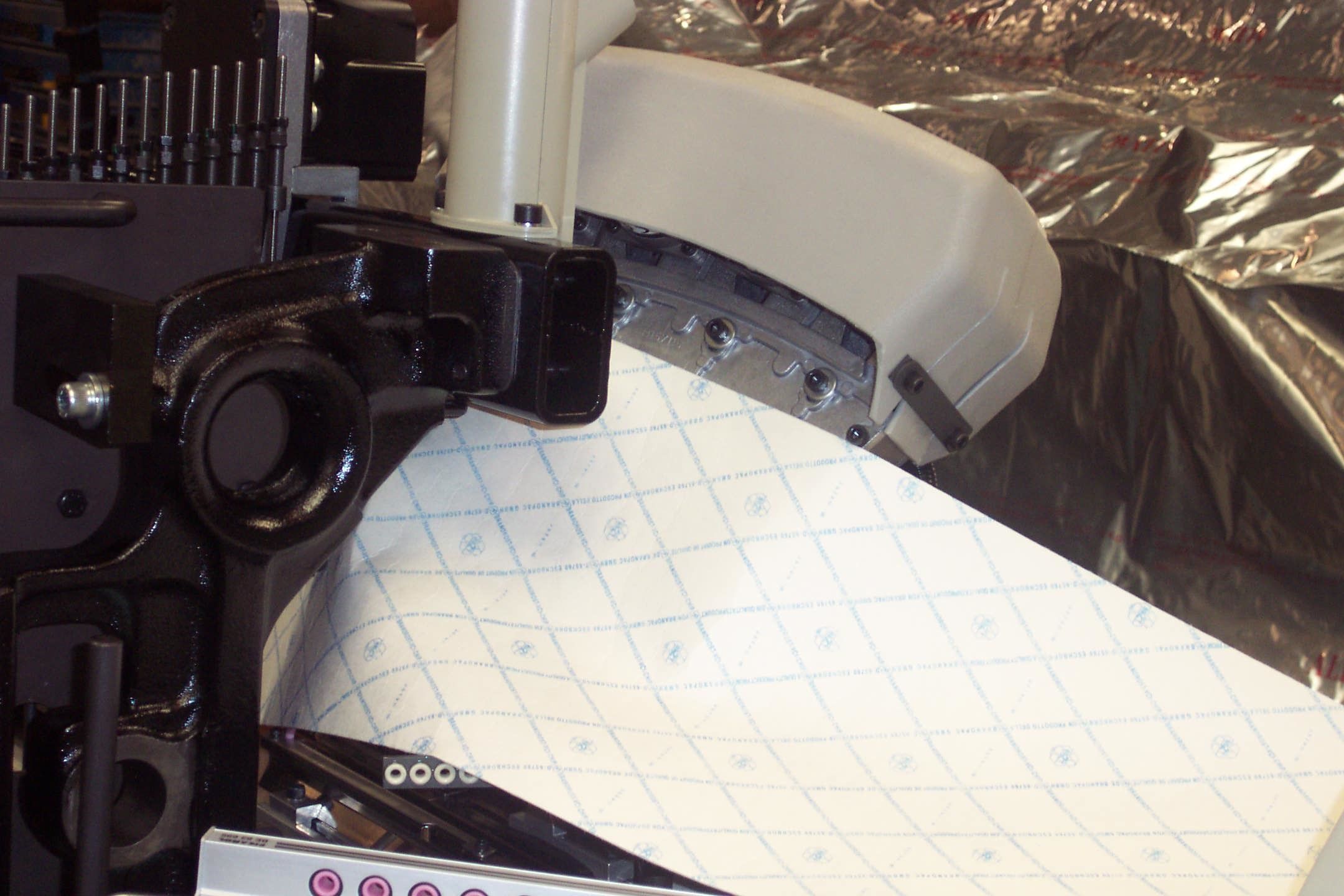

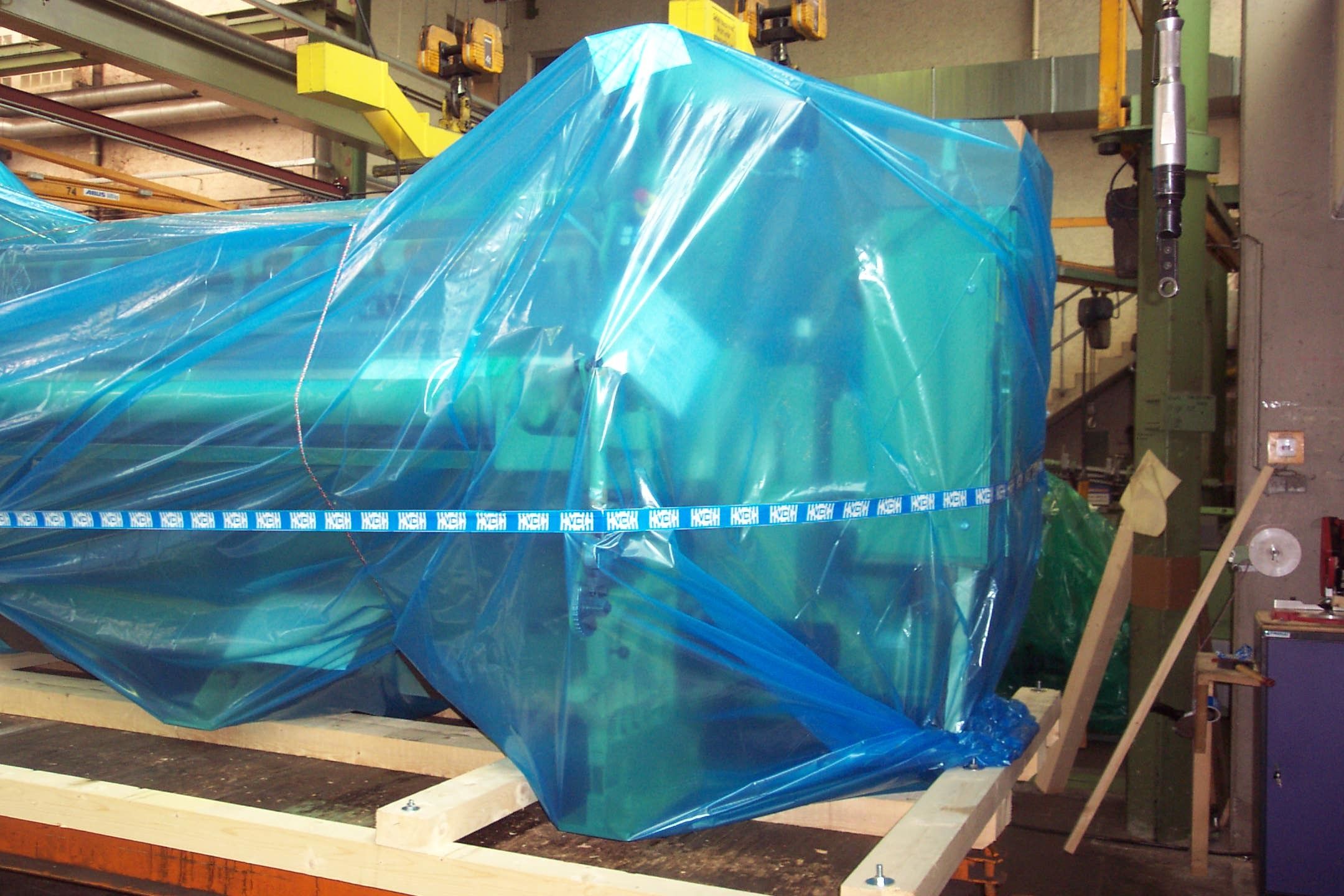

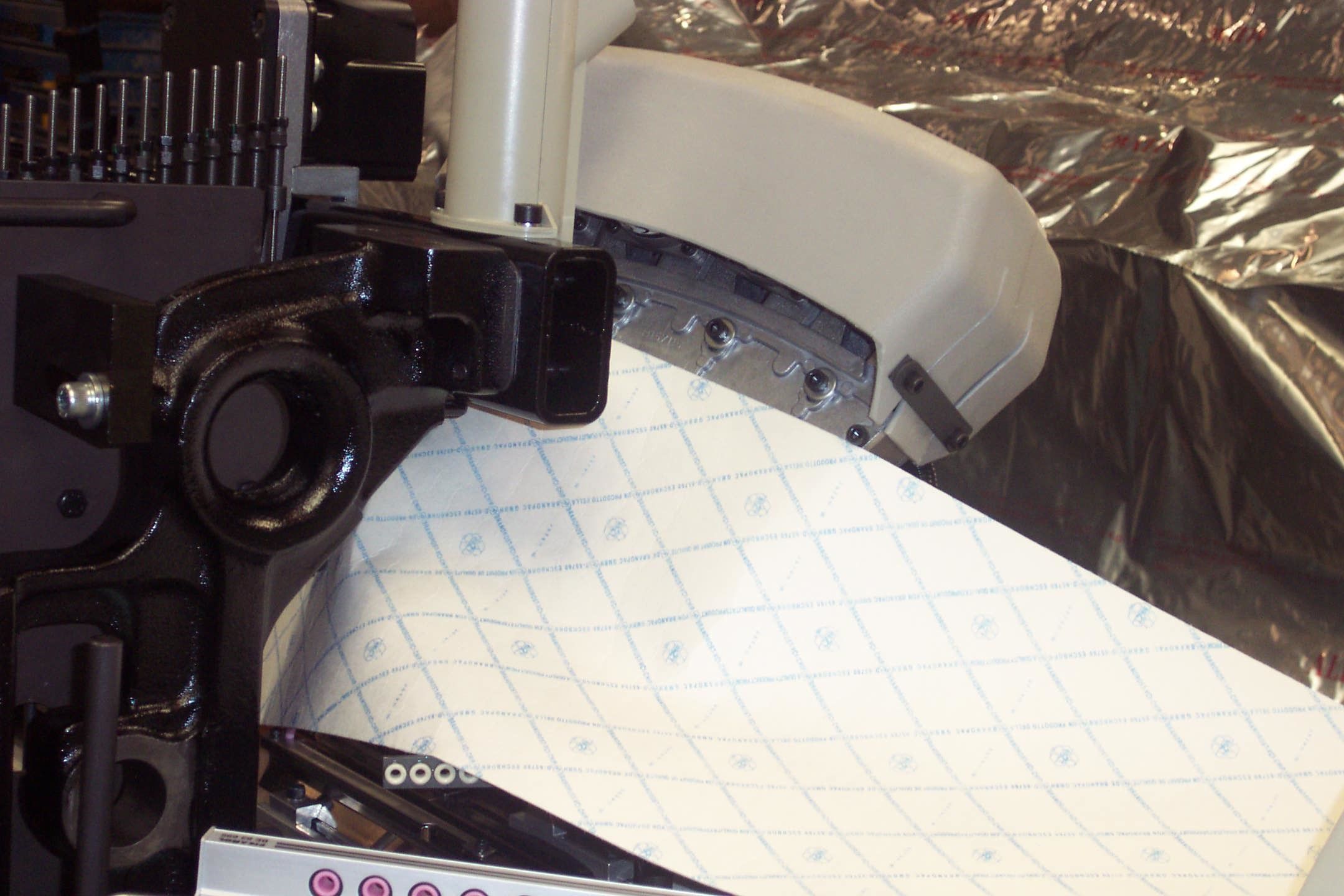

The Branorost Chips minimize the default risk in case of packaging damages compared to the use of drying agents. This increases profitability and enables not only short and long-term storage but also worldwide transport under extreme conditions. The chips function as VCI deposits and establish an efficient VCI atmosphere within closed packages. Furthermore, they possess outstanding cushioning and anti-scratch properties. Branorost Chips combine protection against damage and corrosion by emitting constantly a small amount of active anticorrosion substances inside of the packaging.

Branorost R chip: recommended for steel, cast iron, chrome, block tin, and high-grade aluminium.

Branorost U chip: recommended for steel, copper, and its alloys brass, bronze, high-grade aluminium, chrome, and block tin.

Protection Duration: 3 years maximum in tightly sealed packaging. Depending upon climate conditions

Advantages

- Environmentally friendly corrosion protection based on paper

- Package and anticorrosion protection in one

- Metal parts are ready for use immediately

- Time efficient packaging process

- Easy to dispose of and recyclable

- Non-hazardous material

BRANOpac is certified according to ISO 9001 and ISO 14001 Development of customized solutions possible

Specification

|

Brand |

BRANOrost Chips |

|

Packaging Type |

Cut sheet |

|

Usage/Application |

Industrial Use |

|

Color |

White |

|

Pack Size |

Customised |

|

Material |

Concentrated VCI Paper |

Reliable Corrosion Protection

Branorost R Chips use advanced VCI technology to form an invisible protective layer on metal surfaces. This prevents moisture and contaminants from causing rust or corrosion, making them highly effective for industrial storage and export packaging. Simply place the chips close to or in contact with your metal components for ongoing protection.

Customizable for Versatile Applications

Available in standard sizes or cut to your specifications, Branorost R Chips can be tailored to fit a variety of packaging and protection requirements. Whether you are storing small tools or large machinery parts, these chips adapt easily to your needs.

Suitable for Multiple Metals

These VCI paper chips are engineered to protect a diverse range of metals including steel, chromium, tin, pure aluminium, and cast iron. This versatility ensures optimal use in mixed-metal environments, minimizing the risk of corrosion across your entire inventory.

FAQ's of Branorost R Chips:

Q: How do Branorost R Chips protect against rust and corrosion?

A: Branorost R Chips release volatile corrosion inhibitors (VCI) that form an invisible molecular layer on the surface of metals, preventing moisture and oxygen from reaching and corroding the metal.Q: What sizes are available for Branorost R Chips?

A: These chips come in standard sizes, but can also be cut to any size as per your specific requirements. This flexibility ensures they suit diverse packaging and storage needs.Q: When should I use Branorost R Chips?

A: It is ideal to use Branorost R Chips during the storage or transportation of metal parts such as steel, chromium, tin, pure aluminium, or cast iron to prevent rust and keep them in pristine condition.Q: Where are Branorost R Chips commonly used?

A: They are widely used in industrial storage facilities, packaging plants, during shipments, and by manufacturers and suppliers throughout India who need to protect metal goods from corrosion.Q: What is the process for using Branorost R Chips?

A: Simply place the chips close to or in direct contact with the metal items you intend to protect. Then wrap, store, or ship your products as usual to maintain optimal protection.Q: What are the benefits of using VCI paper over traditional corrosion prevention methods?

A: VCI paper, such as Branorost R Chips, offers clean, dry, and non-intrusive protection without the need for oils or greases, making it safer and more convenient for both handling and final product use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in VCI Emitter Chips Category

BRANOrost Cellulose Chips

Price 1050 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Corrosion protection

Feature : VCI impregnated

Color : White

Shape : Customized

BRANOrost U Chips

Price 1050 INR / Square Meter

Minimum Order Quantity : 1000 Square Meters

Application : Protects steel, cast iron (only on contact), zinc, chromium, copper, brass, bronze, pure aluminium and tin.

Feature : Protection from Rust/Corrosion

Color : White

Shape : cutsheet

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese